Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

The DL-6CYL-800 automatic tea cake pressing machine is applicable for pressing ball type tea, round tea cakes and square tea cakes. Its production capacity is 800-1000 pieces per hour. The sizes of tea cakes that this machine can produce are as follows: square tea cakes (25-40 mm), round tea cakes (25-45 mm), and ball type tea (27-35 mm).

Oolong Tea Rolling Machine specializes in tea rolling and shaping. With precise pressure control, it releases tea juice, enhances aroma, ensures stable quality, and suits green tea, oolong tea, etc.—a top choice for tea enterprises.

DL-CRQ-20Z CTC black tea HRS Gyrovane rotorvane machine mainly used for processing CTC black tea.

The Multi-Function Ride On Type Tea Harvester is a high-performance tool for commercial tea gardens. Featuring ride-on operation, adjustable picking parameters, and integrated collection/sorting, it replaces manual picking to save labor significantly. With 5-10x higher efficiency (0.3-0.8 ha/h) and precision plucking that preserves tea quality, it’s ideal for modern large-scale tea production.

DL-6CHL-CY30 belt type tea dryer use diesel heating, also can use gas heating, drying area 20m2, capacity 105kg per hour, click the photo to learn more details about our drying machine.

Pyramid/Triangle Tea Bag Filling Packaging Machine is widely applicable in tea processing plants, food and beverage companies, health product manufacturers, and OEM/ODM tea brands. It is suitable for packaging various teas, including loose-leaf tea, herbal tea, scented tea, functional tea, and instant tea, making it an essential equipment for upgrading the tea packaging process in both domestic and international markets.

Square Tray DL-6CH-6QB is a square tray baking cabinet-style Tea leaf baking machine, featuring stable temperature control, uniform heating, ideal for batch tea processing with efficient performance.

DL-6CFJ-20 used for black tea and dark tea processing, through the intelligent control of temperature and humidity, let tea oxidation fermentation to the best quality, machine has 5pcs stainless steel tray, capacity 60 kg per batch.

The main function is to inject nitrogen gas after the internal vacuum, allowing the tea to ferment in an anaerobic environment, producing more amino acids (GABA is gamma aminobutyric acid). GABA is a natural chemical substance, equipped with fully automatic vacuum pumping, nitrogen injection and tea fermentation functions. At the same time, it can display gas pressure, nitrogen purity, etc. in real time.

| DESCRIPTION |

DL-6CFJT-15070 , specially designed for GABA tea production, features vacuum extraction to remove oxygen, nitrogen gas generation to maintain oxygen-free conditions, nitrogen injection gaseous for a continuous oxygen-free and oxygen-free environment. fermentation to accumulate y-aminobutyric acid (GABA) in tea leaves, ensuring optimal fermentation results.

| EXPLODED VIEW |

| ① | Control panel | ⑤ | Nitrogen storage tank |

| ② | 304 stainless steel sealing cover | ⑥ | Stainless steel fermentation bucket |

| ③ | Nitrogen generator | ⑦ | Moisture Freeze Dryer |

| ④ | Support casters | ⑧ | Air filtration kit |

| ADVANTAGE |

1. Fully automatic control, automatic vacuum nitrogen filling.

2. Fully sealed, made of 304 stainless steel.

3. Safe 6mm stainless steel cylinder with 3 sets of pressure relief safety devices.

4. Large capacity, 200 kilograms per batch.

5. With the glass window, observe the condition of the tea at any time.

| APPLICATION |

This oxygen-free fermenter specially developed for the production of GABA tea has the following functions.

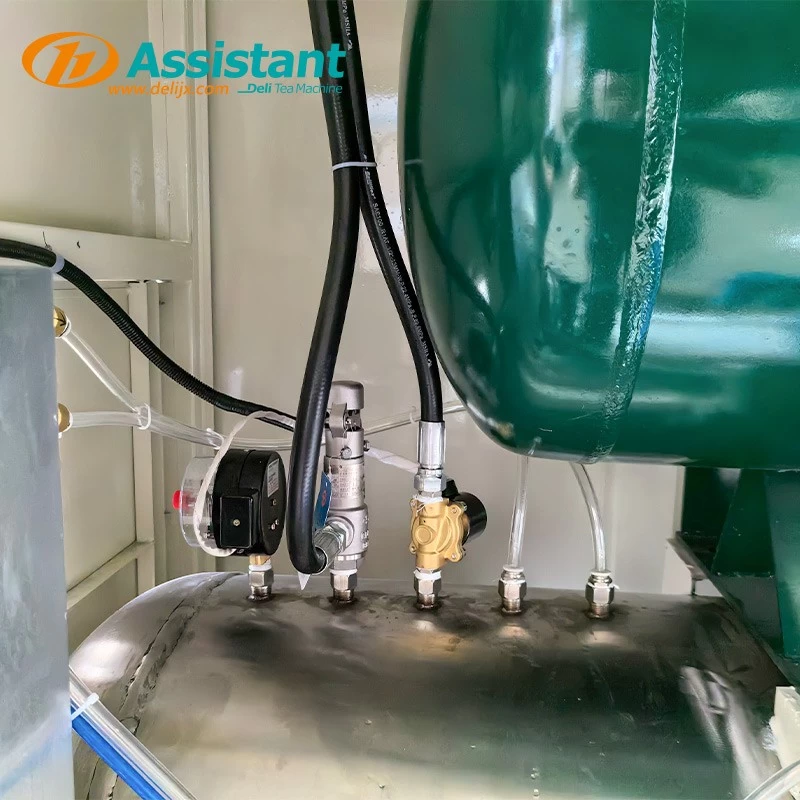

1. Vacuum pumping: The oxygen-free fermentation process should be carried out in an oxygen-free environment, so this tank has a vacuum pumping function to ensure that the oxygen in the tank is completely exhausted.

2. Generate nitrogen: By generating nitrogen, the tank is kept in an oxygen-free state to promote tea fermentation. Nitrogen is a natural gas that does not interfere with the fermentation process.

3. Nitrogen filling: Before fermentation begins, the tank is filled with nitrogen to ensure the continuity of an oxygen-free environment.

4. Fermentation without oxygen: The tea leaves undergo fermentation without oxygen inside the pot to accumulate y-aminobutyric acid (GABA). This specific fermentation process sets GABA tea apart from other types of tea

In summary, this oxygen-free fermentation tank is a crucial tool designed specifically for GABA tea production, ensuring that tea leaves achieve optimal fermentation results in an oxygen-free environment.

| SPECIFICATION |

GABA tea fermentation processing machine spec list:

| Model | DL-6CFJT-15070 | |

| Size | 220*135*210cm | |

| Tension | 220/50V/Hz | |

| Power | 5kW | |

| Nitrogen purity | 99 | |

| Bucket diameter | 715mm | |

| Barrel length | 1500mm | |

| Tank pressure | 0.6 MPa | |

| Minimum vacuum degree | 100PA | |

| Efficiency | 200 kg/hour | |

If you have special needs, it can be customized according to customer needs.

| DETAILS |

GABA tea leaf without oxygen The fermentation tank is equipped with an intelligent temperature and time control system. He has a 99% nitrogen purity and real-time nitrogen pressure display. The device allows you to adjust the vacuum suction time.

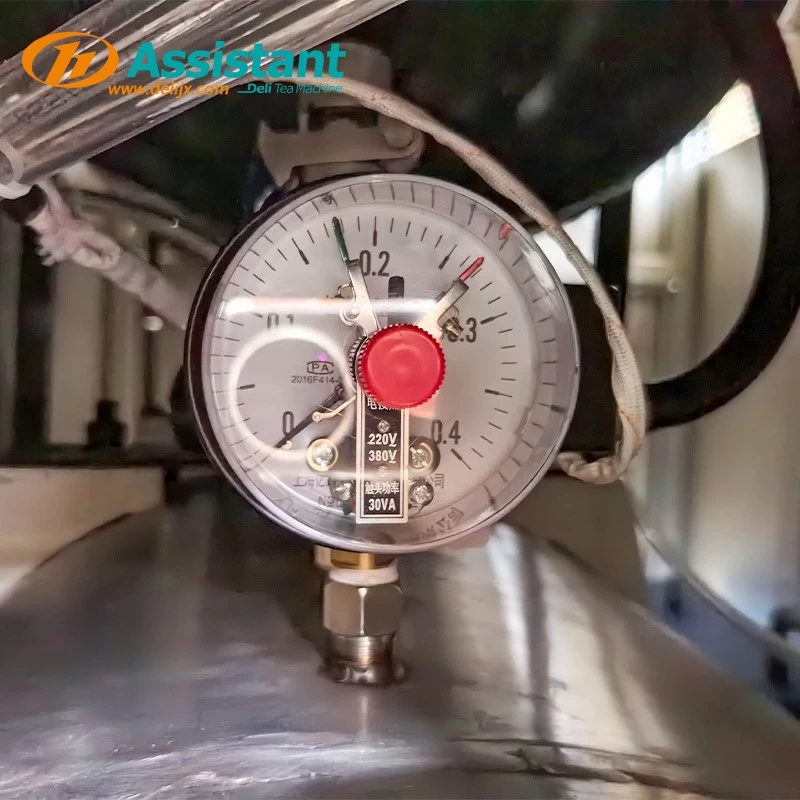

Manometer

You can adjust the safety value of negative and positive pressure in the barrel to ensure the safety of the production process.

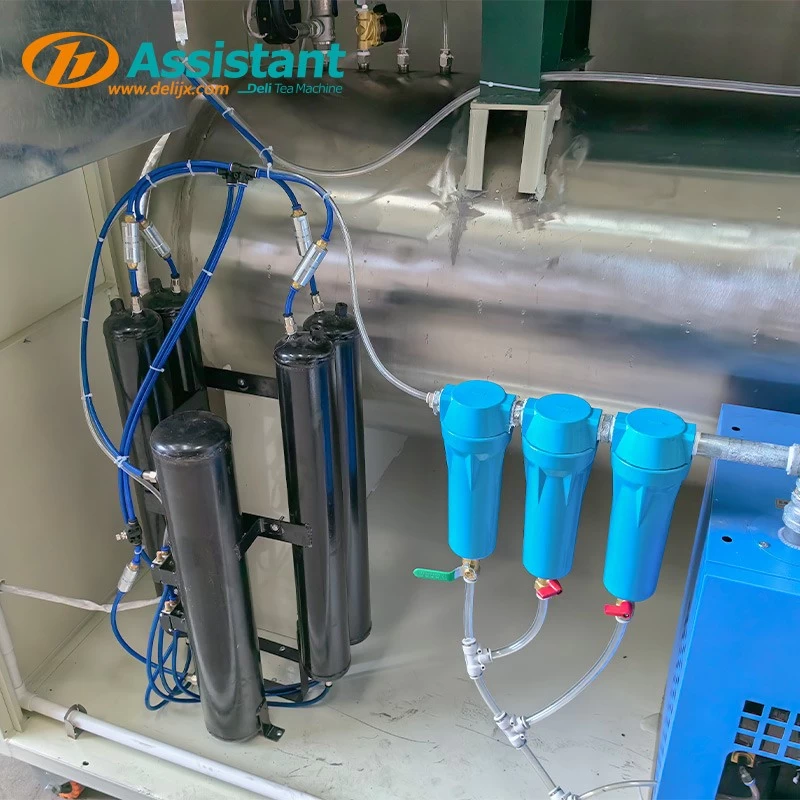

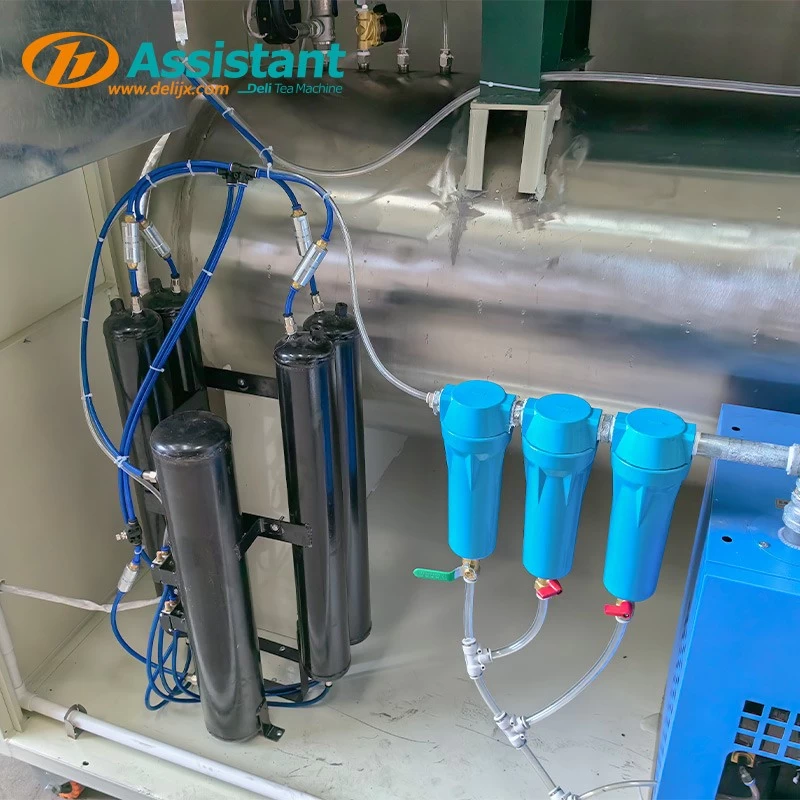

Nitrogen storage tank

* The nitrogen storage tank is characterized by a pressure safety certificate and is equipped with a pressure relief valve. It can also pre-store nitrogen to ensure the machine can immediately go into operating mode when needed.

Air filtration components are important parts of an air filtration system that help remove contaminants and impurities from the fermentation tank.

| PICTURES |

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

↓ ↓ You can also leave your contact details at the bottom. We usually contact you in about 10 minutes ↓ ↓

Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF