As a medium-sized material packaging machine, it can be used for packaging granular and powder products such as tea, nuts, coffee, candy, industrial screws, etc. It has automatic packaging, automatic bag cutting, combined with filter paper and plastic film, and uses a back sealing bag making process. It can produce up to 20 bags per minute.

The Nylon Triangle Pyramids Tea Bag Packaging Machine with Outer Bag is a standout in the tea packaging field. Suited for various teas like black, green, oolong, herbal and flower tea. It makes unique triangle pyramid nylon tea bags with a square rubber outer bag for protection and appeal. Packaging speed is 2000 - 4500 bags/min. Innovation lies in precise control and stability. Advanced tech integrates inner and outer bags seamlessly. High-quality materials and sophisticated structure ensure durability. A great choice for tea makers seeking quality and innovation.

The automatic heat shrink packaging machine for plastic film packaging and sealing is a highly efficient packaging equipment designed to meet the diverse packaging needs of various industries. It uses plastic film to tightly wrap products and then applies heat to shrink the film, ensuring a secure and aesthetically pleasing packaging.

The vacuum inner film packaging machine is for packaging products like tea. Removes air by vacuuming to prevent oxidation and moisture, prolonging shelf life. Has a high-precision weighing system. Inner film protects products. Easy to operate and efficient, ideal for fresh-keeping packaging.

The electric baking cage tea dryer can precisely control the temperature, has rich and diverse functions, is suitable for small tea factories, can replace charcoal baking, and can enhance the aroma of tea.

The Hidden Manual Electric Filter Paper Tea Cup Machine, as a semi-automatic sealing and packaging machine, is suitable for packaging various types of tea. It places tea cups on molds for pressing, precise, fast, simple and easy to use, and can produce an average of 500 cups per hour.

The DL-4CD-35N Electric Tea Picker has a cutting width of 35cm and is equipped with an 18V 5.2Ah cordless lithium battery to eliminate wire interference during operation. The working time can be up to 8 hours, and it can pick 150 kilograms of fresh tea leaves in one hour.

DL-6CY1-15 mainly used for pressing cake tea, brick tea, chocolate type tea, the pressure and time can be adjusted, using hydraulic control, tea shaping is better. Machine has 1 working stations, 1 workers can operate the machine at the same time, 1 hour can press 35kg cake tea.

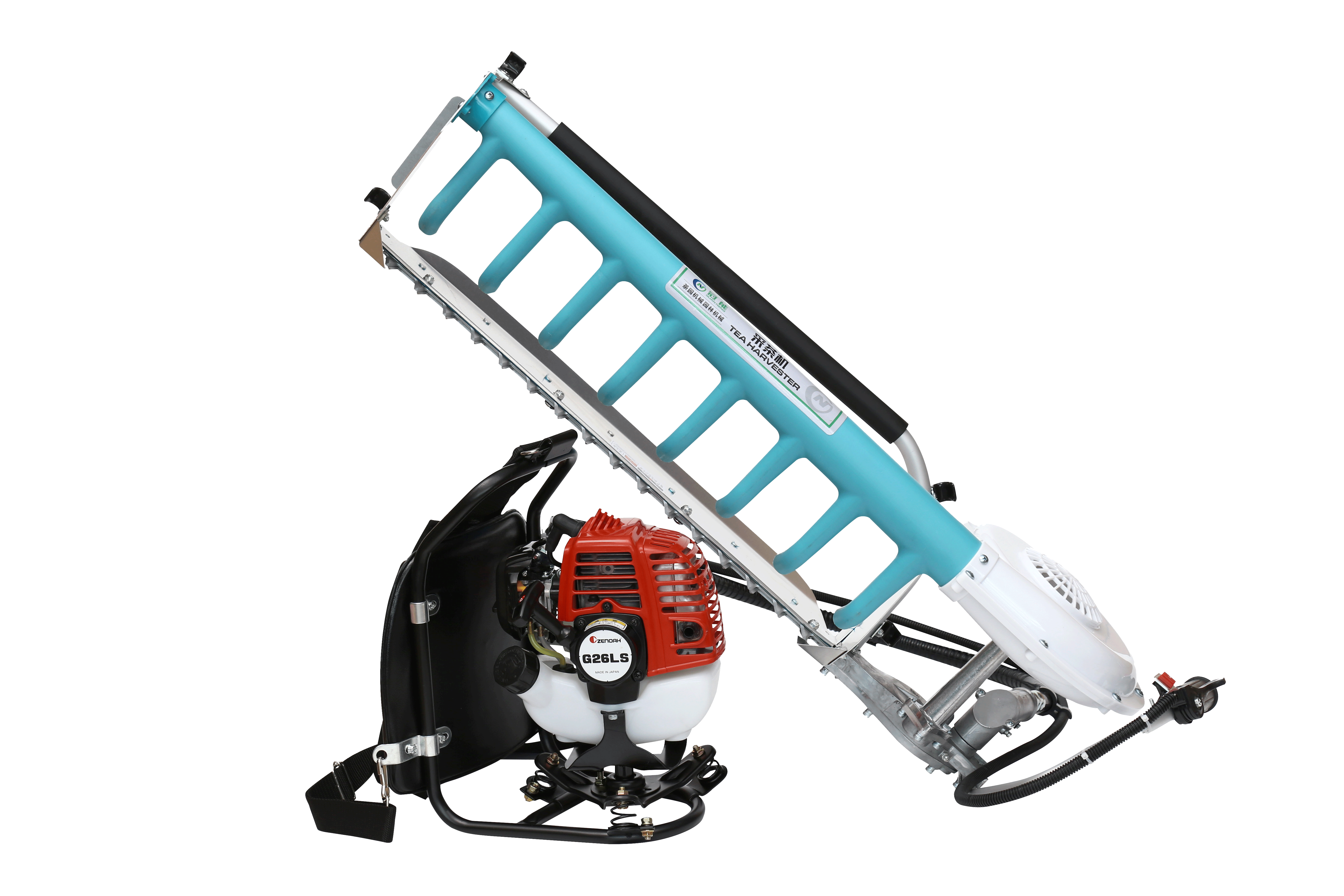

This article provides guidance on choosing a gasoline engine tea harvester by considering factors such as field conditions, performance needs, quality and durability, ease of operation and maintenance, and cost.

Read More

Analyze and compare various models of vacuum tea packaging machines to help you make an informed decision.

Read More

Discover the working principle, usage method, and precautions of the electric baking cage with bamboo basket for enhancing the aroma of tea.

Read More

This blog explores the features and applications of fuel-powered tea harvesters, highlighting their advantages in large tea gardens while also discussing some considerations for their use. In the world of tea harvesting, fuel-powered tea harvesters play a significant role, especially in large-scale tea plantations.

Read More

This blog post discusses the different types of tea harvesters, classified by power source, harvesting method, and operation mode. It provides an overview of the characteristics and applications of each type to help tea growers and enthusiasts understand the available options for tea harvesting.

Read More

Wither is an important link in the tea production process. The main purpose is to moderately dissipate the moisture in the tea leaves, soften the leaves, and facilitate subsequent processing. The following is some introduction about withering tea

Read More

This article introduces the operating guide and scope of application of the tea aluminum foil large outer bag packaging machine. In terms of operation, it includes steps such as installation, preparation, loading, setting, operation, monitoring, and cleaning. The scope of application covers the packaging of various types of tea in the tea industry, suitable for large-volume packaging needs. The aluminum foil material can effectively protect against moisture, light, and oxygen, ensuring the freshness and quality of tea. At the same time, it improves packaging efficiency and reduces labor costs.

Read More

The article may first describe the state and characteristics of fresh leaves. Then, it elaborates in detail on the handmade production process of transforming fresh leaves into black tea, including stages such as picking, withering, rolling, fermenting, and drying. During this process, the unique aspects of handmade production are emphasized, such as the exquisite craftsmanship of artisans and the control over details.

Read More

Discover the fascinating journey of tea from leaf to cup. Explore the various stages of tea production, including picking, withering, fixation, rolling, fermentation (for some teas), and drying. Learn about the art and science behind crafting your favorite cup of tea.

Read More

This blog delves into the detailed production of black tea, highlighting the key steps and their significance.

Read More

black tea, brewing method, tea sets, tea leaves, water temperature, tea amount, brewing time

Read More

This blog delves into the exciting world of wireless battery tea harvesters. It explores their potential to revolutionize the tea harvesting process, highlighting their benefits and addressing the obstacles they face on the path to widespread adoption.

Read More